|

| Tristan Marcoux élève 2019 Jul 20· 4 min read |

[ en fr ] |

|

| Tristan Marcoux élève 2019 Jul 20· 4 min read |

[ en fr ] |

Every generation introduces new technological advancements. For example, the landline became a wireless cell phone which can now be used to play games, use the internet, and read novels. From first being theorized in 1959 by Richard Feynman, nanotechnology has come a long way since then. Nanosensors are one of our generation’s least understood and most innovative advances.

Before speaking about nanosensors, nanotechnology as a whole should be explained. In brief, nanotech is the manipulation on an atomic, molecular, and supramolecular level of atoms. The unit of measurement most commonly used is a nanometer (nm). A Nanometer is one-billionth of a meter (10^-9). In comparison, a sheet of paper is 100,000nm thick. Nanosensors are minuscule devices (with sensing dimensions smaller than 100nm) that are mostly used in nanomedicine, nanoelectronics, and molecular engineering. They can measure quantitative properties (and some qualitative properties) and convert them into detectable signals. Those signals can be analyzed and processed into metrics.

There are three broad groups of nanosensors; Optical nanosensors, chemical nanosensors, and physical nanosensors. To start, optical nanosensors are made with a substrate (binding unit) with fluorine and a photoactive component. The photoactive component has organic layers and an absorbing material. When the two materials are bound together, the fluorophores can absorb light of a certain wavelength. That absorbed light emits a quantum of light with the equivalent energy of a particle between the ground and excited states. The optical nanosensor can detect ambient light and react to it. It can also sense enzymatic, DNA, and antibody interactions due to its reaction to light and its partially organic materials.

Next, chemical nanosensors are created using a chemical recognition system (a molecular receptor) and a physicochemical transducer (a device that can convert a physical quantity into an electrical signal). The sensor transforms information such as chemical composition, the presence of an element, in particular, the chemical activity, and concentration into a signal.

Thirdly, physical nanosensors are created just like the previous ones are made but with physical measuring devices (like a thermometer, scale, etc) instead of a chemical recognition system. The physical nanosensor can detect pressure, force, mass, temperature, and displacement, all in a tiny area.

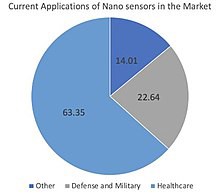

These types of nanosensors help with everything from our daily lives to the planet’s well-being. Infrared nanosensors can be placed in all buildings. With a relatively cheap cost, it can detect if a person is armed or carrying some illegal things. Plus, they can be used with carbon nanotubes to make the fastest computers. Nanosensors also have great medical purposes. CNT-based fluidic sensors study the stress of cells and blood vessels. They are useful in diagnosing many illnesses. Optical nanosensors can use fluorescence resonance energy for glucose monitoring. Chemical nanosensors can help with the environment by sensing chemicals in the air (i.e. carbon dioxide), water (i.e. mercury), and in agricultural grounds. With their accuracy and quickness of measurements, they will innovate the world on a technological level. These pieces of nanotech can even detect pollution in the ozone layer.

These sensors are made through nanofabrication. In simple terms, nanomanufacturing and nanofabrication are using nanoscaled materials to create tiny devices. There are three types of ways to create a nanosensor. The first production method is called top-down lithography. It involves carving a block into the desired shape and adding components. It has just started to use nanosized components and is usually of micro size. The second way to produce nanosensors is the bottom-up method. Minuscule components such as molecules and atoms are assembled into sensors. The downside is that moving individual atoms have only been achieved in a laboratory test. Mistakes are common and it would be exceedingly difficult to mass-produce them. Finally, the third method to assemble nanosensors is self-assembly. This involves having a set of components that would assemble itself automatically. Production can be rapid and without errors. Though we get closer every day, we don’t have the right tools to use this method yet.

An idea to improve nanofabrication is to use blood as an energy source instead of batteries for the medical nanosensors. Right now, nanotechnology is too small for the need of batteries but in the future, when medicinal nanosensors need a power source to do hundreds of actions at a time, using blood as a “haemaelectric” energy source could diminish the use of batteries, which are toxic to the human body and the environment, as well as remove one of the biggest components in a nanosensor.

To conclude, nanotechnology has come a long way since 1959. Nanosensors are on track to revolutionize science and every facet of the world as we know it. People say the sky is the limit. With nanotechnology, there is no limit!